China Economic Professional Facing Lathe Machine for turning HDPE Flange, Steel Flange, Shipyard propeller, impeller, tyre mold, alloy wheel, Pipe, etc

Characteristics of facing lathe machine, horizontal lathe machine:

1. Both Conventional Horizontal Lathe and CNC Facing Lathe Machine are available according to customer's special request and demands. PLC or DRO are all Ok.

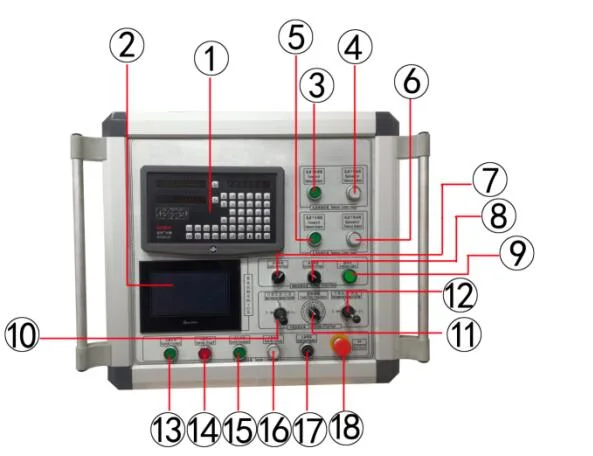

2. Specially designed a kind of convenent /flexible operation panel system, which obtained our national patent. For the conventional horizontal facing lathe machine, this kind of operational panel system can be installed.

PLC & Digital Readout Instrument: This machine is installed double axis digital readout system of X& Z axis which realizes the digital display function by digital readout ruler installed on the sliding plates of both X and Z axis. The digital readout ruler mainly includes ruler and reading head. When the sliding plate moves, the reading head can realize exact readings and display through the LCD. The number displayed may be accurate to three decimal places with high display accuracy.

3. We specially designed a kind of convenient Separate Handwheel Operation Unit which installed on the side of operation panel. For the conventional horizontal lathe, we equipped with both conventional and electrical control handwheel device. The operator can exactly operate the work-piece like positioning, part-verify, etc

Our company advantages:

1. More than 50 years experience in designing and manufacturing standard and customized lathe machines.

2. We have our foundry which can control the casting parts quality very well. We have professional hardening/quenching furnace used for castings surface treatment to ensure high stability, rigidity and accuracy of horizontal lathe machine.

3. Professional machining equipment such as 12 meters long gantry CNC Grinding Machine, gantry milling machine, CNC Boring Machine, Drilling Machine, Horizontal CNC Lathe Machine for machine main parts like headstock , tailstock, guide rail ,cutting tool carriage, chuck turning

4. Professional technical team to provide both 3D & 2D drawings of horizontal Lathe Machines, roll turning lathe, Facing Lathe Machine, etc to customers after order confirmation and before production. In this designing method, we can make a perfect customized lathe machine for customers.

5. Immediate reply and actions for after-sale service , even after 15 years, we can also provide the easy damaged lathe machine parts and accessories immediately, becaue for each horizontal lathe machine and vertical lathe machines, we have one complete drawings. and we have enough spare parts for each lathe machine in stock.

| CK60 series - Flange Lathe Floor Type CNC Lathe | ||||||

| Type | Unit | CK6016 | CK6018 | CK6020 | CK6025 | CK6030 |

| Swing Diameter over machine bed | mm | φ1600mm | φ1800mm | φ2000mm | φ2500mm | φ3000 |

| Chuck Diameter | mm | φ1000mm | φ1250mm | φ1600mm | φ2000mm | φ2500mm |

| Chuck jaw seat length | mm | 400mm | 400mm | 500mm | 500mm | 500mm |

| Work-piece length | mm | 500mm | 500mm | 500mm | 750mm | 1000mm |

| Work-piece Weight | T | 2T | 2T | 3T | 3T | 3T |

| Spindle Diameter | mm | φ190mm | φ200mm | φ220mm | φ220mm | φ260mm |

| Spindle speeds | r/min | 14-108r/min | 14-108r/min | 4-160r/min | 4-106r/min | 4-106r/min |

| X Axis Stroke | mm | 800mm | 900mm` | 1000mm | 1250mm | 1500mm |

| Z Axis Stroke | mm | 350mm | 350mm | 350mm | 350mm | 350mm |

| X Axis Rapid Speed | mm/min | 2500mm/min | 2500mm/min | 2500mm/min | 2500mm/min | 2500mm/min |

| Z Axis Rapid Speed | mm/min | 2000mm/min | 2000mm/min | 2000mm/min | 2000mm/min | 2000mm/min |

| Cutting Tool Carriage Size | 300*300 | 300*300 | 300*300 | 300*300 | 300*300 | |

| Cutting Tool Carriage Size | mm | 40*40mm | 40*40mm | 40*40mm | 40*40mm | 40*40mm |

| Motor Parameters | ||||||

| Main motor power | KW | 11KW | 11KW | 15KW | 18.5KW | 22KW |

| Feed Motor Power of X Axis | KW | 2.3KW | 2.3KW | 2.3KW | 2.3KW | 2.3KW |

| Feed Motor Power of Z Axis | KW | 2.3KW | 5.5KW | 5.5KW | 5.5KW | 5.5KW |

| Lubrication Motor Power | KW | 0.37KW | 0.37KW | 0.37KW | 0.55KW | 0.55KW |

| Machine Accuracy | ||||||

| Cylindricity | mm | 0.03/300mm | 0.03/300mm | 0.03/300mm | 0.03/300mm | 0.03/300mm |

| Platness | mm | 0.03/300mm | 0.03/300mm | 0.03/300mm | 0.03/300mm | 0.03/300mm |

| Roughness | Ra | Ra3.2 | Ra3.2 | Ra3.2 | Ra3.2 | Ra3.2 |

| L*W*H Machine Dimensions | mm | 2800*1850*1800mm | 2800*1950*1900mm | 2800*2000*2000mm | 3250*2650*2650mm | 3500*3300*3200mm |

| Machine Weight | T | 6T | 9.5T | 11T | 12.5T | 15T |

Rermarks:

1. The above models Horizontal Facing CNC Lathe Machine are the standard configurations, we can also design and manufacture customized lathe machines according to the user's workpiece features.

Semi-metal cover cnc lathe machine exported to Chile, Norway, Argentina, Colombia, Pakistan, India, Iran, Thailand, Mexico, etc,

1. We provide professional technical training for users' operators and maintenance staff to enable them to properly use and operate the lathe and carry out normal maintenance.

2. Warranty period: One year after acceptance of the lathe.

3. In case of any quality problem found during operation, the factory will dispatch personnel to the user's location within 48 hours (domestic users) & within 3 days (Foreign Customer) and the technical staff won't leave before resolving the malfuntion.

4. The company will freely provide different electrical and mechanical parts for the purchased lathe timely within warranty period.

5. The company will provide lifetime guarantee for the consulting services in terms of application, maintenance, repair, renovation, etc of equipments.

For more details, please feel free to contact us. Thanks!

Tag:Conventional horizontal lathe, Alloy wheel turning lathe, Facing CNC Lathe, Flange turning lathe, conventional lathe, Flat Bed Lathe