1. Product Description

Normal Hydraulic Press Cylinder for Press Machine

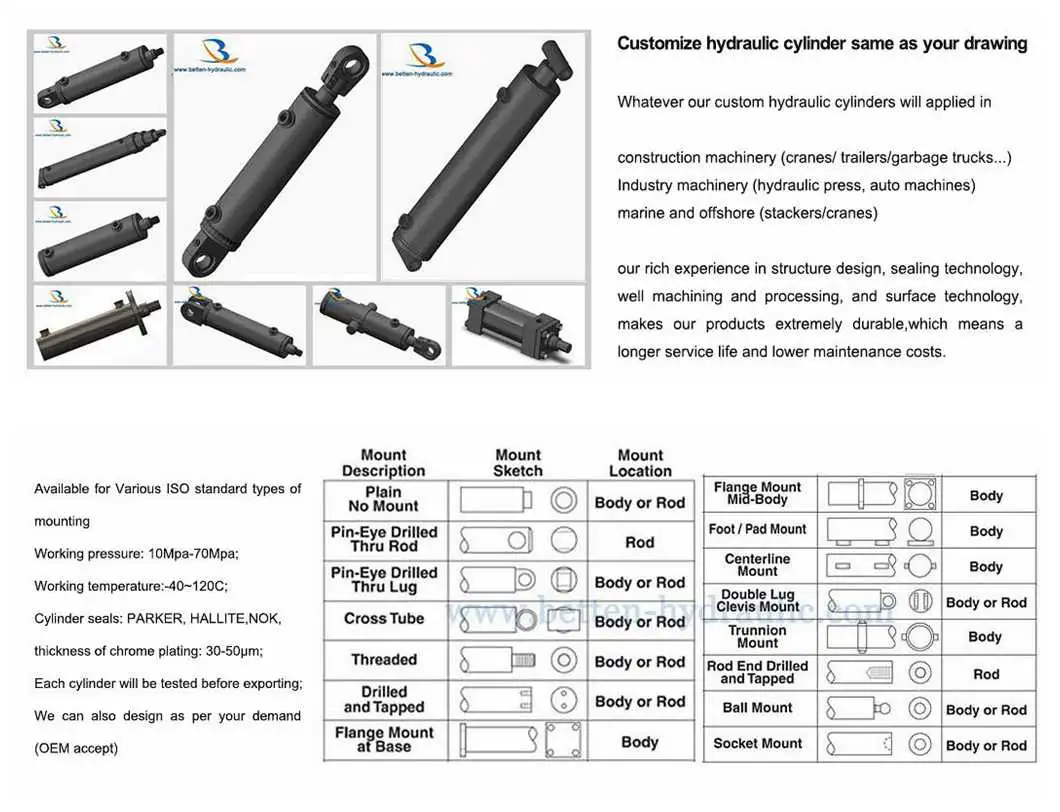

1. Application: hydraulic press machine

2. Installation: Two ends with earring, with flanges, with trunnion, with U clevis, with ball;

3. Working pressure: 10Mpa-30Mpa;

4. Working temperature:-40~80C;

5. Cylinder seals: PARKER, HALLITE,NOK,

6. The thickness of chrome plating: 30-50μm;

7. Every cylinder will be tested before exporting;

8. We can also design as per your demand (OEM accept)

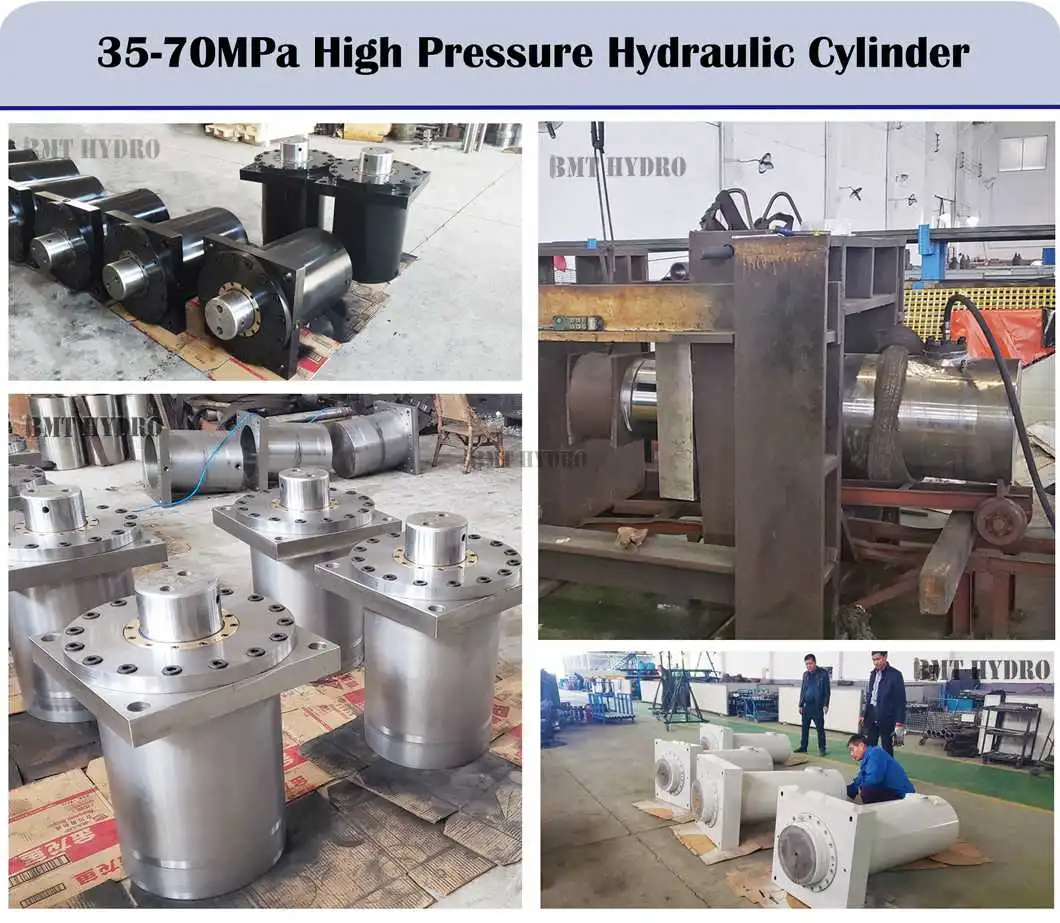

30-70MPa High Pressure Hydraulic Press Cylinder for Press Machine

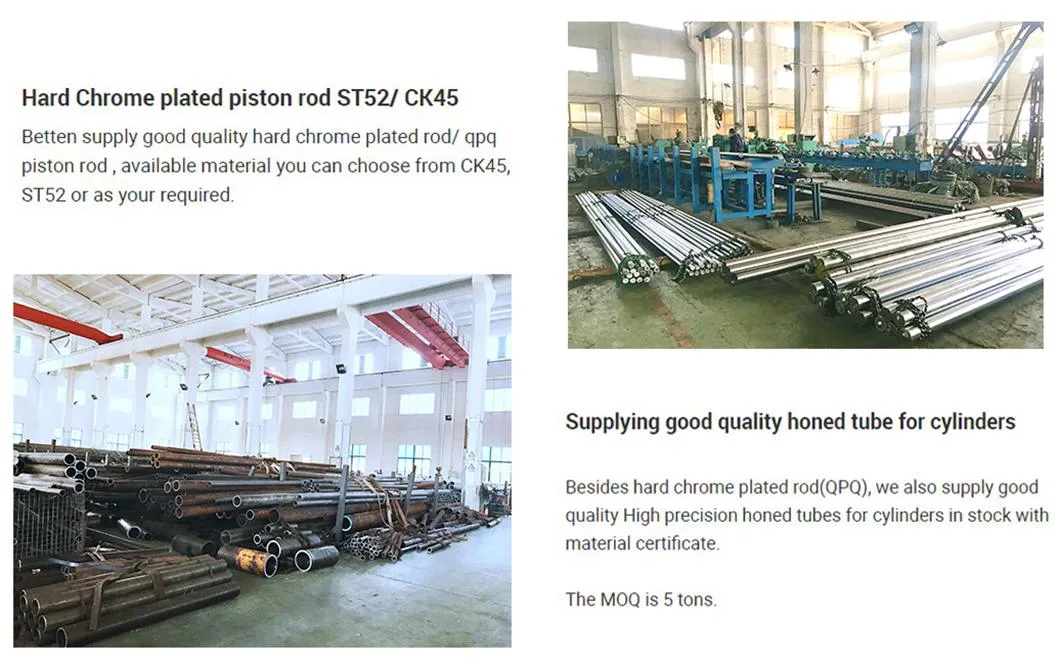

Betten Hydraulic - 25 years experienced Hydraulic Ram Manufacturer

80% Rexroth quality with 30% Rexroth Price

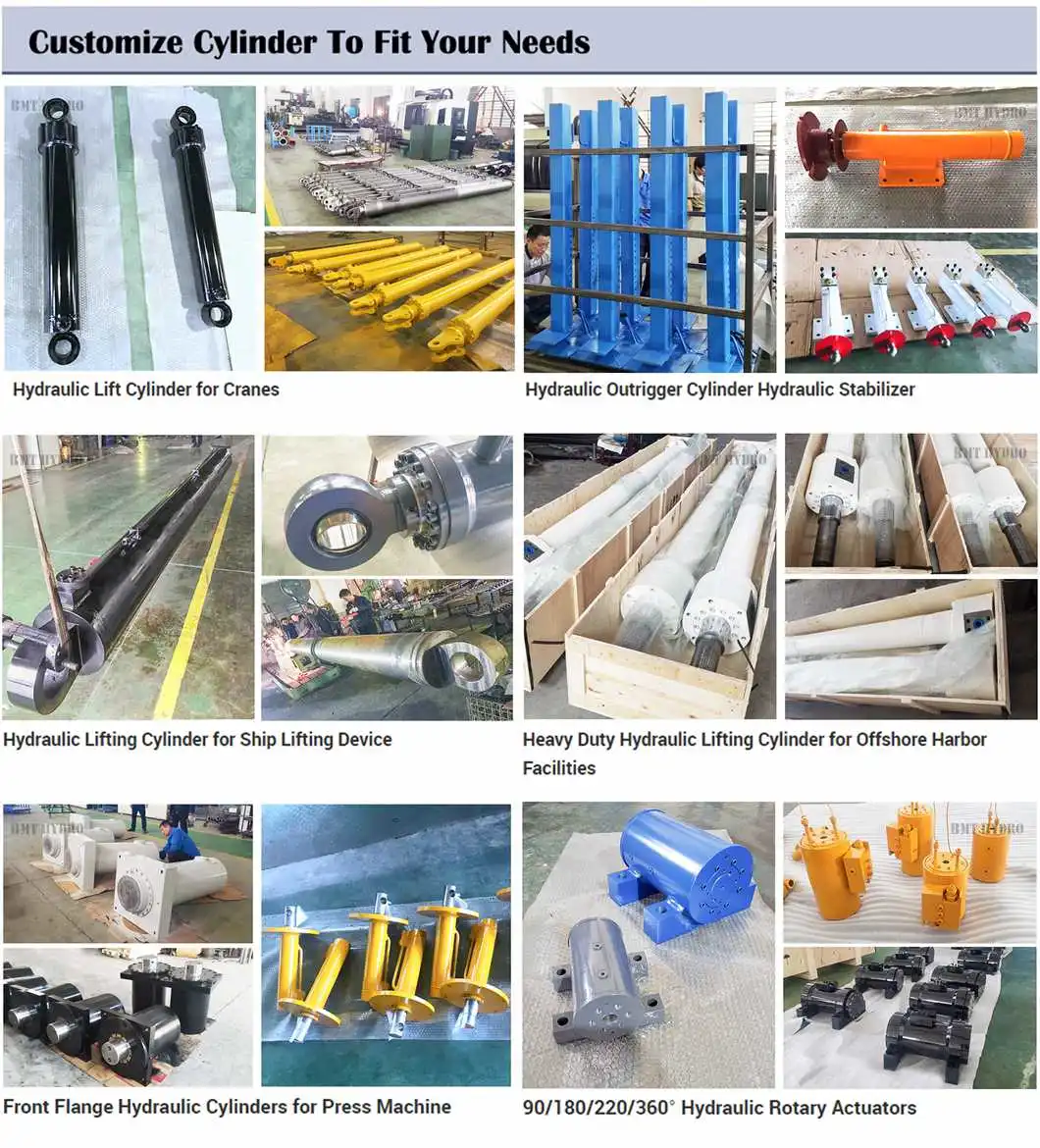

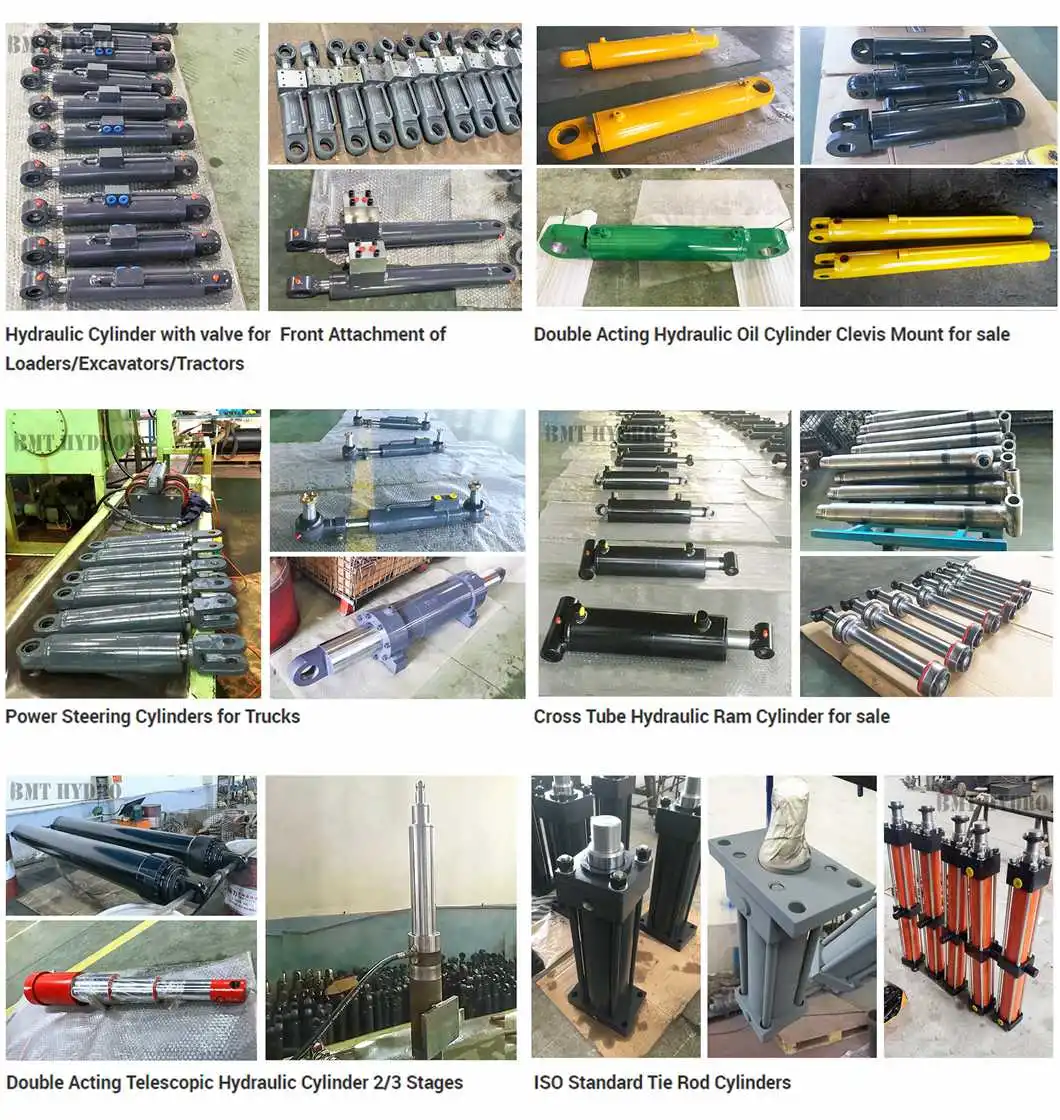

Custom Hydraulic Cylinders to fit your needs

Betten's double acting hydraulic cylinders could combine reducer union, piston rod, seal kits, Cylinder bore and other body parts with our careful Trundle processing. Each cylinder before sold should be tested by Ultrasonic detector, spectrograph, CMM, metallography, chrome thickness tester to confirm its capacity. As well, Betten's piston cylinders lead other suppliers by their flexible production schedule and reliable manufacturing technology.

Betten has exported to Australia, Southeast Asia ,Middle America and South American and build cooperation with some world famous customer like LIUGONG Machinery, Chalco,BOSCH, Haier, SAINT-GOBAIN,Shanghai Boiler, HTC etc.

2. Technical Data

| Product | same quality as rexroth hydraulic cylinder/ hydraulic rams |

| Stroke | 20mm-16000mm |

| Inside Cylinder Tube Dia. | 20-1500 mm (1.5 - 40 inch) |

| Liner material | copper (prolongs the life cycle of cylinder) |

| Hydraulic cylinder tube material | Carbon steel, Alloy steel, Stainless steel |

| Piston Rod Dia | :12 - 500 mm (1/2 - 20 inch) Hydraulic Cylinder Piston Rod should be hard chrome plated to minimum thickness of 35-55 microns and polished to 0.15 um Ra |

| Chome Plated | Cr, Ni or Ceramic |

| Design Pressure | Max 700 bar (10150 PSI) |

| Weight | Max 60 tons |

| Valves | SUN (USA),or famous Chinese brand with same quality to PARKER |

| Seals Type | PARKER (USA), MERKEL (Germany) or NOK (Japan) |

| Liner material | copper (prolongs the life cycle of cylinder) |

| Bearings | LONGXI (China) or SKF |

| Painting | follow with customer requirement or 3-coat marine painting |

| Certificate | DNV, ABS, Lloyds, BV, GL, KR, NK, RINA, RS and CCS |

| Application | Construction vehicle (Cranes/ Dump truck/ Forklift/ Excavator/ ,etc), mine, metallurgy, shipping, water conservancy, etc. |

3. Betten - Hydraulic Cylinder Manufacturer to custom hydraulic jack for you

Betten Hydraulic-Built Hydraulic Products to Fit Your Needs

As an experienced Hydraulic Cylinder Manufacturer and distributer, Betten Machinery is built to develop the overseas business of Boli Hydraulic & Pneumatic Technology Co., Ltd which is known as a professional manufacturer of Oil Cylinder,Pneumatic Cylinder, Hydraulic System and Related Spare Parts in East China.

Our factory cover an area of over 5000 square meters and have around 100 stuff including a technical team with more than 20 engineers. Our workshop equipped with over 30 sets of manufacturing and testing machines including machining center, numerical control machine, argon welding machine, plasma cutter etc. Betten has gained the certification of ISO 9001:2008 and certification of Product Quality Supervision and Inspection Center of Wuxi City. Meanwhile, Betten also got customers' satisfaction for reasonable price, timely delivery and good after-sale service.

With the fast development in the past 20 years, we have gained much experience and technology in making various types of long hydraulic cylinder with our expert team. Our products are widely used in equipment such as machine tool, metallurgical equipment, forging machine, kiln equipment, brick machine, plastic machine, car manufacturing machine, construction equipment for road and bridge, wielding machine, port facilities, test machine, fully auto line and we have gained a lot of world famous customer like LIUGONG Machinery, Chalco,BOSCH, Haier, SAINT-GOBAIN, Shanghai Boiler, HTC etc.

4. Manufacturing Process

Each Betten Hydraulic Ram has suffered rigorous process and inspection to promise the good quality for our customer.

1). Design Services

Our design team has experience in cardan shaft relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2). Product Services

raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→Packing→Shipping

3). Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4). Research & Development

We usually research the new needs of the market and develop the new model when there is new cars in the market.

5). Quality Control

Every step should be special test by Professional Staff according to the standard of ISO9001 and TS16949.

6). Certification

Should your products require testing and certification to comply with international standards, we can arrange this with independent, fully recognized testing companies such as SGS, Intertec, Bureau Veritas, Lloyd's Register or the testing company of your choice.