Overview

Material | 1). 60% Wood powder |

2). 30% HDPE | |

3). 10% Chemical Additives | |

Features | 1. With natural wood grain and looks like nature wood, less timber problems |

2. Recycled materials, environmental friendly, saving forest resources. | |

3. Easy to install and low labor cost. | |

4. High degree of anti-UV and color stability. | |

5. Cutting and drilling like timber. | |

6. Weather resistant, suitable from -40ºC to 60ºC. | |

7. Resistant to termite and insect attack, will not split, rot or warp. | |

Brand Name | Kelai wpc |

Size | 160*160mm |

Color | Red, Brown, Yellow, Coffee, Grey, Black, Chocolate or customized |

Package | Pallet with Belt:Boxes |

Delievery time | 15~20 days after we receive the deposit |

Loading Port | Shanghai/Ningbo |

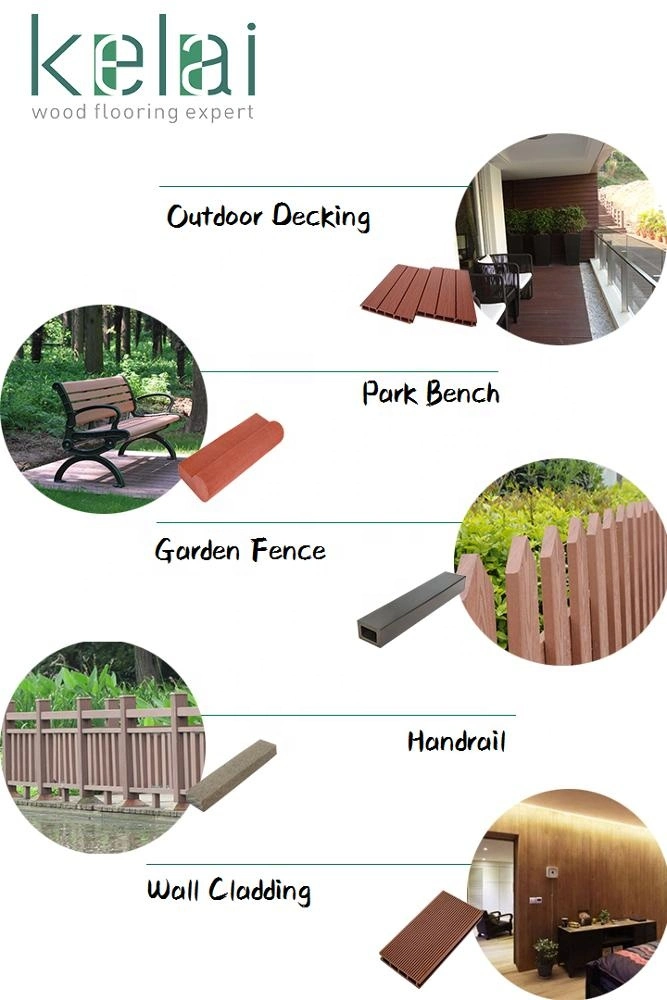

Range of Use | Garden, Lawn, Balcony, Corridor, Garage, Pool&SPA Surrounds, Boardwalk, Playground |

Supply Ability | 10000 Ton/Tons per Year |

Product Application

Product Description

Model Number | KS160H160 |

Material | 60%-65% natural wood fiber 30%-35% of eco-friendly HDPE materials 5% -10% Chemical additivel |

Size | 160*160mm |

Surface treament | Sanding |

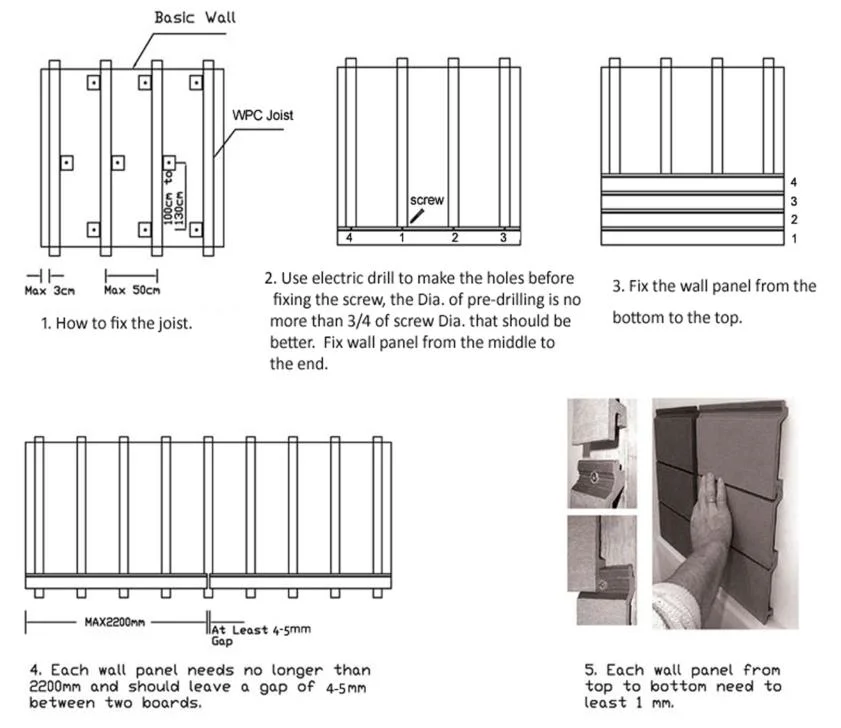

Installation

Packing & Workshop

FAQ